South Bulli Colliery

(see also Gibson’s, Bellambi West, Allied Meridian, Bellpac No. 1, NRE1 and Wollongong Coal – Russell Vale Colliery )

(1862 - 1997)

Rev 9.5- March 2016

Opened: 1862

Owner: Taylor & Walker

Closed: 1864

Re-opened: 1887

Owner: Saywell & Wilson

Purchased: 1890 (E. Vickery)

Purchased: 1901 (Bellambi Coal Co Ltd)

1858 – Coalmining commences in the Bellambi area (Hale’s Bellambi mine)

1861 – Proposed as the Russell Vale Colliery.

1862 – Taylor & Walker open a mine on land owned by the Osborne’s

1864 – The mine closes due to the depressed market

1864 – A failed attempt to re-open the mine

1886 – Re-opens under the control of Thomas Saywell as the South Bulli Colliery. A new jetty and railway is constructed.

1887 – The first coal is shipped in November

1890 – Ebenezer Vickery purchases the mine.

1902 – The Bellambi Coal Company purchases the mine.

- Sellers – “The Illawarra Coalfield – A brief history to 1905” The AusIMM Conference, Illawarra May, 1976.

1862 – Operations commence at the South Bulli Colliery in the Bulli seam. #

1864 – Operations cease after encountering a basaltic dyke which had partially cindered the coal.

1885 – Taken up by Messrs Saywell and Wilson

1885 – Inspection by Illawarra Mercury – “seam of coal at Russell Vale is so good that surprising stood so long unworked. Three men working there for last 10 months with expectation of having up to 100 by start 1886 and a production of 1000 tons/day – Mr. Wilson, Managing Director. Some 300 tons of plant has been relocated from the Ringwood Colliery, including a locomotive, a large haulage engine of 50-60 h.p, rails etc. A new jetty is to be built at Bellambi and the intent to purchase their own steamers”. (Ill Merc 28/11/1885 p2)

1887 – September. “The South Bulli Company’s jetty at Bellambi is approaching completion” (Australian Town & Country Journal, 3rd Sept. 1887)

1887 – October. The prospectus for the formation of The South Bulli Coal Company, Limited to purchase the mine from Thomas Saywell, [see addendum] (SMH 15/10/1887)

1887 – November 12th, South Bulli Mine & Bellambi Jetty formally re-opened at Russel Vale by Saywell & Wilson. Jetty was 2,085 feet long. (SMH 14/11/1887)

1888 – The Bellambi Coal Co. Ltd formed operating the Bellambi Mine

1888 – 57 men employed supplied with 14,000 cfm of air (DoMAR 1888)

1889 – Second Bellambi Jetty constructed. ***

1889 – “Russell Vale Colliery commonly known as Wilson’s Pit…..” (Ill Merc 17/10/1889 p2)

1889 – “South Bulli Colliery better known as Wilson’s Pit…..” (Ill Merc 7/11/1889 p2)

1889 – Fatality – 8th Feb. Andrew Tressider, miner, by fall of top coal. 120 men employed supplied with 15,000 cfm of air. A new air shaft reaches coal at 80 ft. from surface is sunk (DoMAR 1889)

1890 – Ebenezer Vickery buys out Saywell & Wilson***

1890 – 140 men employed supplied with 24,000 cfm of air (DoMAR 1890)

1891 – Fatality – 14th May. Thomas Tresseden?, miner, injuries by firedamp. 130 men employed.84 new brick stoppings along main intake installed (DoMAR 1891)

1892 – 245 men employed for 140,774 tons produced. Endless wire-rope system adopted during previous 6 months (DoMAR 1892)

1893 – About 200 men and horses employed u/g supplied with 45,000 cfm of air (DoMAR 1893)

1894 - About 150 men and horses employed u/g supplied with 40,000 cfm of air (DoMAR 1894)

1895 - About 200 men and horses employed u/g supplied with 48,000 cfm of air (DoMAR 1895)

1896 – About 250 men and horses employed u/g supplied with 49,500 cfm of air (DoMAR 1896)

1897 – A large “Waddle” fan started up during December, producing 50,000 cfm more than produced by the two furnaces. (DoMAR 1897)

1898 – Fatality – 11th Jul. Alexander Learmouth, 60, deputy, injuries by wagon on the surface incline (DoMAR 1898)

1899 – South Bulli Colliery – Owner: - E. Vickery. Manager: - John McGeachie. U/managers: - Michael Phillips, Robert Wragg, John Hopkins. (DoMAR 1899)

1900 – 241 employees u/g, 64 at the surface for 150,691 tons produced. (DoMAR 1900)

1901 - 289 employees u/g, 73 at the surface for 246,364 tons produced. (DoMAR 1901)

1901 – South Bulli Colliery acquired by The Bellambi Coal Co. Ltd

1902 – 25th Oct. Mr F. G. Waley, general manager of the Bellambi Coal Co., gives notice that Mr Thomas Cater would act as manager of the Bellambi and South Bulli Collieries during the absence of Mr George Cater, on leave. Approx. 448 men and boys are employed, the mine being ventilated by a Waddle fan, intaking through the two haulage tunnels (DoMAR 1902)

1903 - "Safety Lamps" introduced to the colliery.

1904 – Fatality – 11th Nov. Bartholomew Metcalfe, 24, miner, killed by fall of coal (DoMAR 1904)

1904 – 557 persons now employed. The 20 ft diameter Waddle fan was replaced by a 26 ft. “Walker’s Indestructible” fan which also ventilates the Bellambi Colliery. (DoMAR 1904)

1905 – 480 employed u/g with 109 on the surface (DoMAR 1905)

1906 - 15th Jun. Mr F. G. Waley, general manager of the Bellambi Coal Co., gives notice of the appointment of Mr. A. J. Miller to act as manager of the Bellambi and South Bulli Collieries during the absence of Mr. A. E. O. Sellers, on leave. (DoMAR 1906)

1907 – Fatality – 11th Sept. John T. Pallier, 50, miner, coal fall to head. (DoMAR 1907)

1908 – Fatality – R. S. Osborne, the driver of one of a 3 engine collision on the South Bulli tramline, collapsing a short period after the incident. (Scrutineer & Berrima District Press 8/02/1908, p4)

1908 – Fleet of 4 coastal colliers operating (Bellambi – Sydney) Last shipment 14/12/1953

1908 – The Goodman coal cutting machine and Little Hardy Pickwick percussive machine are working satisfactorily, an excavation for a new incline, which has been in progress now for 5 months.

A tunnel is being driven in the 4 ft. seam to connect with the workings in the top seam. (SMH 13th Jan 1908 pp8)

1911 – Fatality – 19th Sep. Cecil Patterson, 26, bank headsman, struck by loaded wagon. (DoMAR 1911)

1913 – Commenced supply of electricity to Bulli Shire (Until December 1959)

1916 – Fatality – 3rd Mar. William Mackey, 29, roadman, struck by runaway tubs. (DoMAR 1916)

1917 – Fatality – 6th Feb. Sydney A. Hill, 18, assist mechanic, electrocuted installing telephone cable. (DoMAR 1917)

1917 – Fatality – 23rd Apr. Harry Critcher, 25, miner, fall of coal. (DoMAR 1917)

1917 - The Sassafras Saw Mill was built by Robert Cram Snr. with his brothers Jack and Arthur. Responsible for building the mill were A. E. O. Sellers (Superintendent, Sth Bulli Colliery), P. C. Prior (Chief Clerk, Sth Bulli Colliery) and Hircullies (Surveyor, Sth Bulli Colliery) plus the employees of the colliery. Up to 80 pit horses are stabled outside Sth Bulli Colliery in the early 20th century.

1917 – An underground transport system for employees is installed

1923 – Preparations in progress for the sinking a new shaft in the catchment area (DoMAR 1923)

1924 – Preparations for a new shaft are still under way (DoMAR 1924)

1924 – A duplicate fan in course of erection (DoMAR 1924)

1925 – A double inlet Sirocco fan, 126” in diameter, was installed and placed in operation, the old fan to be used as an auxiliary in case of emergencies. (DoMAR 1925)

1925 – Fatality – 11th Nov – A shiftman sustained a slight abrasion to the right foot on 22nd October, dying of blood poisoning. (DoMAR 1925)

1926 – Notice was received by the DoM that the workings of Bellambi Colliery will in future be part of the South Bulli Colliery, the whole of both collieries in future to be known under the name of South Bulli Colliery. (DoMAR 1926)

1926 – Sth Bulli reports as having 540 men employed u/g and 132 at the surface. (DoMAR 1926)

1927 – A ventilation shaft has been sunk to 1032’, expecting to hit coal within few feet. (DoMAR 1927)

1928 – The shaft holed into the Bulli seam at 1065’ on 8th Feb. The shaft is 17’ in diameter and passing 120,000 cfm as a downcast shaft.

1928 – A bathhouse for the miners is constructed

1929 – Jan. 12th – No.1 Ventilation Shaft strikes coal

1934 – Fatality - 10th Apr – William Williams, miner, by a fall of face coal at 10 Right. (DoMAR 1934)

1934 – Fatality - 28th Aug - Osmond Crowther, miner, by a fall of face coal at 12 Right. (DoMAR 1934)

1935 – May 24th – First “arcwall” coal cutter placed in service

1935 – Fatality - Sept 9th - Arthur Reeve, miner, face fall. (DoMAR 1935)

1936 – Second “arcwall” coal cutter in service

1947 – 2 x scraper loaders commenced work

1947 – Advert: - Miners for Sth Bulli; Shiftmen £2/10/- per shift; Wheelers £1/7/3 per shift Youths 12/7d to 21/4d as per experience as clippers. (Ill. Merc. 28/02/1947 p8)

1947 – Fatality – John Robert Padgett, boss wheeler, natural causes, excessive strain lifting skip, cerebral haemorrhage (31/03/1947) (DoMAR 1947)

1947 – Advert: - Ventilation Shaft Attendant; small cottage for man and wife. Electric Winding Cert. necessary. – Apply Manager South Bulli Colliery. (Ill Merc 24/8/1947 p8)

1949 – 4 x Mavor & Coulson loaders installed

1949 – Fatality – Kevin Mason, wheeler, jammed between full skip and roadside timber (19/09/1949) (DoMAR 1949)

1950 – Fatality – Stephen Carollo, miner, crushed between set of empty skips and rib timber (26/01/1950) (DoMAR 1950)

1950 – Mrs Laura Carollo awarded £1,000 as compensation by the Workers Compensation Court for the death of her husband, Stephen Amplio Carollo at Sth Bulli Colliery (SMH 8th Jun 1950)

1953 – New brick bathhouse completed

1953 – Surface workshop upgraded

1954 – No. 2 Ventilation Shaft (u/c) completed

1954 – August – Change from scraper loaders to a track mounted L600 loader, 29U cutter and 2 x battery locos (all Jeffrey)

1955 – Decline belt conveyor installed from portal to screens

1955 – Automatic telephone system installed (surface)

1956 – Second Jeffrey L600 loader installed

1959 – March 9th – First Lee Norse continuous miner in Australia plus 2 x Jeffrey S/cars

1959 – April 10th – Contract hand mining system ceases

Lee Norse continuous miner at Sth Bulli

1960 – Second Lee Norse CM, 1 x Joy CM, Joy roof bolter plus 4 x Jeffrey S/cars

1960 (Oct) – 1962 (Jan 17th) – Major reorganisation of colliery included:-

Installation of Coal Preparation Plant, stockpiling & recovery system

Panel conveyors to u/g bin then to surface via main trunk belt c/v system

Fan ventilation for continuous miner faces

Installation of an u/g bin

Recovery of “Gibson’s Tunnel” for 53 chains (1.066 km) with a drift from Gibson’s Tunnel extension to the main haulage

4.5 miles (7.24 km) of haulage road re-laid

A new pit top & transport system for men and materials

1961 – 5 miles (8 km) of 36” (910 mm) neoprene c/v belting, including 5 trunk belts installed and supplied by

Dunlop Aust., Goodyear Tyre & Rubber Co. & Apex Belting for The Bellambi Coal Co Ltd, a subsidiary of Consolidated Gold Fields Aust. Ltd. – Mine & Quarry Mechanisation, 1968.

1962 (Jan) – commenced producing coal for a 410,000 ton contract for Japan

1962 – Second Joy CM with roof bolting rig plus 2 x Jeffrey S/cars installed.

Snapshot of Sth Bulli Colliery in 1962;

Panels- 3 shifts (2 x production, 1 x maintenance), first workings of bord & pillar system only.

Face Equipment - Lee Norse miners with timber jacks, Joy 1CMs (some with roof bolters & timber jacks), Jeffrey shuttle cars, Joy & Fletcher roof bolters. Hi Flow auxiliary fans replacing brattice ventilation to face.

Coal transport u/g- 36” belt from boot (no feeders) to 36” cross belt to 48” belt into u/g bin. Panel belts rated at 300 tons/hr. at 400 ft./min.

Underground Storage -

Bin drift - 6’ x 9’ x 140’ @ 1:3.17 containing 48” c/v @ 600 t/hr (prov. for 900 t/hr)

Bin - circular w/- 22’ diam. top, 40’ deep, concrete lined with 250 tons capacity. Feed

to main conveyor by Lockers vibrating feeder.

Main Conveyor – 20,520’ in 5 flights (42,000’ of 36” cotton, nylon, duck belting), operating at 400 ft/min and 400 t/hr (with capacity for 600 ft/min x 600 t/hr).

Surface – 36” c/v to 4” screens. +4” through 36 x 36 roll crushers to 36” decline c/v to a 500t bin. From bin by road truck, conveyed to dump or fed to coal preparation plant.

Washery – Dry screened 3/16” = feed 4”x3/16” + 3/16” product. Coal prep screens ½” = feed 4”x0”.

Plant capacity - 350 t/hr using an ACCO Drewboy bath system.

Associated Cokeworks:-

The Federal Coke Company Pty Ltd.

A wholly owned subsidiary of the Bellambi Coal Co. Ltd

Established in Wollongong supplying coke for foundries and non-ferrous metallurgical plants.

Coal (1 ¾” x 0”) transported by road to the battery of 45 compound, rectangular, beehive ovens.

The Mount Pleasant Coke Co. Pty Ltd.

A wholly owned subsidiary of the Bellambi Coal Co. Ltd

Established in Nth Wollongong supplying coke for foundries and non-ferrous metallurgical smelters.

Coal (1 ¾” x 0”) transported by 9 ton rail wagons to the battery of 44 compound, rectangular, modified beehive ovens.

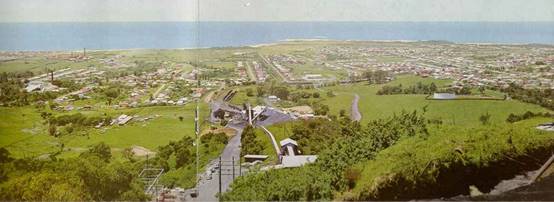

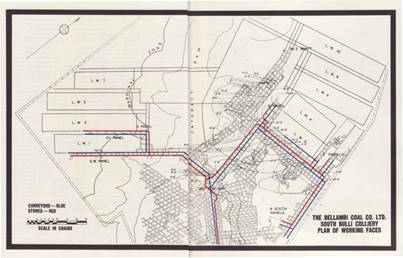

Sth Bulli Colliery circa 1962

Extracts from Brochure for “The Bellambi Coal Company Limited” 1962

1964 - #3 vent shaft commenced planned for completion in 1965 (DoMAR 1964)

1964 – Economic working with CMs difficult – decision to longwall the Bulli seam. #

“Mine and Quarry Mechanisation 1965”

1965 – First L/Wall installed in Bulli seam. #

1965 – Sth Bulli #3 Shaft commissioned as a “regulated intake” shaft and during December being converted to a “return” shaft. September, a longwall face was put into service, some 180 yards in length. The system includes an Anderson-Boyes 200 hp ranging drum shearer mounted on a Mecco face scraped conveyor with Gullick Seman 6 leg chocks and a Mecco gate road stage loader.

Four diesel, rail mounted, personnel cars were placed in service during the year (DoMAR 1965)

1967 – Development commences in the Balgownie seam, 15m below the Bulli seam, using a low seam, oscillating ripper type miner.

In the Bulli Seam extraction of the second longwall panel commenced in July and was completed in less than 6 months. Average production was 1,300 tons/day. The longwall equipment was transferred to #3 longwall over the annual vacation. (DoMAR 1968)

1969-70 – South Bulli Colliery is divided into two separate mines under separate managerial control. South Bulli “A” Colliery comprising the surface, coal washery and Balgownie Seam workings and South Bulli “B” Colliery comprising the Bulli Seam workings inbye the cross measures drift between the Balgownie and Bulli Seams.

Sth Bulli “A” development work has been progressing in using lift and fender system of pillar extraction below the old workings and goaf areas of the Bulli Seam. Longwall equipment has been obtained for the 4 ft seam expected to commence operating in September. (DoMAR 1969-70)

1970 – Snapshot – D. J. Simes, Asst. General Manager, Bellambi Coal Co. Ltd operates two mines at South Bulli;

“A” Mine, Balgownie seam, 4’ section

“B” Mine, Bulli seam 7 – 11’ section

L/Wall installed in “B” in 1965 with a second in 1970.

L/Wall for “A” was delivered in August 1970.

Mine & Quarry Mechanisation, 1970.

1971 – L/Wall installed in the Balgownie seam (1.3m thick, Ss roof, shale floor) Problems with flooded, overlying Bulli seam workings, goaf and remnant pillars. #

Roadways height increased by 0.6m of floor cut. Improved longwall production. #

>5,000t/day & 20,000t/wk achieved. 11 units extracted. #

1971 – Sth Bulli “A” – Development using Joy 9 CMs for the formation of main headings and a second longwall face gate roads. (DoMAR 1970-71)

1973 – Roof support changes from 2.1m x 19mm expansion shell to 2.1m x 24mm resin anchor bolts. Alternating timber (2 x bolts) and “W” straps (3 x bolts).

1973 – Sth Bulli “A” – further development depends on draining the water from the overlying Bulli Seam goaf (DoMAR 1972-3)

1974 – Sth Bulli “A” – difficulties still persist in draining the overlying water. Sth Bulli “B” – the d/cast shafts were fitted with surface booster fans, effectively increasing air flow (DoMAR 1974)

1974## - Sth Bulli “B” installed its first Longwall unit in 1965, a further 2 units in 1970.

Balgownie Seam (below remnant pillars in Bulli seam)

Gullick Dobson 6 leg chocks, 400 ton total yield load

110 chocks completing 5th L/W block in 1974 having mined >600,000 tons

Bulli Seam

Type “A”, strong Ss roof

Gullick Dobson 7 leg chocks, 500 ton yield

4 L/W blocks >750,000 tons by 1974

Type “B”, Shale roof

Westfalia 4 leg chocks, 560 ton yield

## “Roof Support of the Longwall System” D. Fawcett (Mines Superintendent, The Bellambi Coal Company, Ltd.) a paper presented to the “Support in Pillar Extraction, Wollongong, 1974.

1975 – Sth Bulli “A” – Decision to reduce the number of development headings. Problems still persist with the drainage of the overlying impounded water. Sth Bulli “B” – A new shaft has been commenced with another in the planning stage (DoMAR 1975)

1975 – First integrated system using Taiheyo Engineering Co. equipment, Mitsui Miike Shearer –The Bulli seam block of 131m wide x 960m was extracted in 146 days. #

1975 – Aug; Bellambi Coal Co sacks 889 South Bulli Colliery workers. (Ill Merc, 03/12/1999)

1976 – Bulli Seam currently (and also projected) 2.3 – 2.9m dipping 1:50. Frequent stone rolls

to 1.5m. Gate roads 22.9 x 68.6m c/Lines.

14 longwall blocks extracted since 1965

Westfalia 4 leg chocks – Bulli sm.

Gullick 7 leg chocks – Bulli sm.

Balgownie Seam Operations:- 1.2m thick, 9m below the Bulli sm. Longwall operation

since 1970 – Gullick 6 leg chocks.

“Longwall Operation at South Bulli Colliery” Ross, K. (Operational Manager – The Bellambi

Coal Co. Ltd.) a paper presented to the AusIMM Conference, Illawarra, May 1976.

1976 – Sth Bulli “B” – Development keeping head of longwall extraction. No 4 Shaft is nearing completion (DoMAR 1976)

1977 – Sth Bulli “A” – Long walling below the Bulli Seam workings had continued, the dewatering has progressed. Sth Bulli “B” – development work continues in the vicinity of No. 4 Shaft (DoMAR 1977)

1978 – No 4 Shaft commissioned as a friction winder carrying men and the sinking of Shaft No. 5 commenced (DoMAR 1978)

1979 – Work commences on sinking #5 shaft and reaches the Bulli seam within the period (DoMAR 1979)

1982 – Balgownie seam operations cease. #

1986/87 – Proposal to update (replace) 1 x longwall unit plus all but supports of 2nd unit. #

# Addendum to Brochure (no details available)

1991* – July 24th – 3 Fatalities - South Bulli Colliery – (Austen & Butta)

Outburst in W12 panel – on a reverse fault

Resulted in the suffocation of three (3) miners by carbon dioxide released by the outburst.

BHP Engineering undertook inseam seismic across fault in May, 1991 Results 1/8/1991 (No indication of outburst potential detected)

Deputy Manager: - Lawrence Crisp

Mine Manager: - Michael Ogilvie

1992 *– July –Shell Coal Australia buys out Austen & Butta

*[News media reports of Coroner’s Inquest, 1992]

1980** – Employed >1200

1997** (March) – employed 300

1997** (April) – employed 160

**Currently wholly owned by Shell Coal Australia

**From a Media release by Bellambi Collieries Pty Ltd [Shell Coal Aust.] 26/3/1997

Paraphrased: - “phased reductions at South Bulli commenced October 1996 on schedule with first group of employees to leave on 4/5/1997”

**Need to phase down due to geological conditions: - Barry Robinson, Manager, Bellambi Collieries.

**Currently 299, to lose 120 4/5/1997 with further 139 in August, 1997 leaving 40 to run Care & Maintenance

**In January a change in gas regime and geology in western reserves proved too expensive.

**Activity concentrated in small reserve, high costs but geologically better.

**1996 encountered igneous plug.

**In October, 1996, commenced phased reduction in operations with development to end in April 1997 and Longwall in August 1997.

** “South Bulli to Close in August” (1997) an article from “The COA Lamp” 14/5/1997

***Illawarra Unity Vol. 1 No. 3 1998

1995 – South Bulli Colliery owned by Bellambi Coal Company Pty Ltd [Shell Australia Ltd. 100%]

1997 – September purchased by Allied Coal Pty Ltd from Shell and renamed Bellambi West Colliery with Allied Plant Services Pty Ltd the major shareholder at 100%.

1998 – Bellambi West Colliery owned by Allied Bellambi Collieries Pty Ltd [Allied Meridian Pty Ltd 100%]

2000, 20th Dec. – Fatality due to roof fall (DoMAR 2001)

#2001 – (Gibson’s Tunnel) Russel Vale Colliery abandoned by “Thin Seam Mining”

2002, 29th January – Allied Holdings closes Bellambi West after 4 ½ years with loss of 190 jobs. (Ill Merc. 15/03/2002)

#Bellpac Pty Limited (backed by Great Pacific Capital Ltd.) purchases Bellambi West Colliery renames it Bellpac No. 1 Colliery

2003 – March, Great Pacific Capital provided a loan to Bellpac, the owner of the Bellambi project, repayable by March 2005. (Dec 2003 also provides $6 mill. to Newpac for the acquisition of Nardell Colliery).

#2004 – August, Bellpac closes Bell Pac No.1 Colliery with loss of 35 jobs.

2005 - 30th March, Gujarat NRE purchases Bellpac No. 1 Colliery renames it NRE No. 1 Colliery #(Ill Merc. 30/03/2005)

2005 – July, Bellpac enters a joint venture with a subsidiary of Austcorp Group Pty Ltd for the development of the Bellambi project. Loan to Bellpac rearranged, extending term to July 2008.

2008 – Great Pacific Capital Ltd suspends trading on ASX 9/5/2008

2009 – May, Bellpac Pty Ltd placed in receivership.

2009 – Sept. 3rd, Bellpac Pty Ltd (in liquidation) wound-up voluntarily. (Commonwealth of Australia Gazette, 15th September, 2009)

2012 – December, NRE No.1 Colliery currently owned by Gujarat NRE Australia Pty Limited.

2013 – 17th Oct - Shareholders vote in favour of Jindal Steel and Power Ltd taking over Gujarat NRE Coking Coal, the Australian subsidiary of Gujarat NRE Coke.

2014 – 25th Feb - Shareholders vote to change the name of Gujarat NRE Coking Coal to Wollongong Coal Limited.

2014 – NRE No.1 Colliery formal name change to Russell Vale Colliery by Wollongong Coal.

2015 – Wollongong Coal announces cessation of coal production at the Russel Vale Colliery with the loss of 80 jobs. (Ill Merc 01/09/2015)

2015 – 16th Sept. Wollongong Coal sacks 40 workmen as first part of the 80 announced 1/9/2015. (ABC News Online 16/09/2015)

2016 – Wollongong Coal ordered to remove its coal waste stockpile from its Russell Vale Colliery site with restrictions on transportation times to daylight hours. (Ill Merc – 18/03/2016)

2016 – Wollongong Coal is removed from the All Ordinaries Index of the stock exchange. Shares last traded at 0.5c ea. Wed 16/03/2016. (Ill Merc – 18/03/2016)

The Sydney Morning Herald, Saturday 15 October 1887 page 6

THE SOUTH BULLI COAL COMPANY, Limited.

Guaranteed Dividend of 10 per cent per annum for three years

Capital £80,000 in 80,000 shares of £1 each.

Provisional Directors; John C Smith; Alfred W Gilles; William H Armstrong; Thomas Cowlishaw; Thomas Saywell.

This company has been formed to acquire and purchase the valuable developed coal property known as South Bulli, with the plant and the guaranteed contract for the purchase of the coal at the jetty for a period of five years.

The property consists of 700 acs of leasehold land for 50 years, at a royalty of 9d. per ton on round or large coal and 20 acs of freehold; also railway and jetty for shipping coal.

The seam proved and opened out ready to work is known as the Bulli seam and is 7 ft. to 10 ft. in thickness.

The Vendor, in asking for payment in cash of £40,000, merely requires a portion of his cash outlay, as there has been expended in opening out and plant £45,750 which is fully borne out by Messrs. Cox and Seaver’s valuation of same as appended.

The Vendor has exercised great judgement in developing the colliery. All the work has been done with the object in meeting the demands of a large output. The plant and machinery are all of the latest type.

The Vendor has made a contract with Messrs. Woollcott-Waley and Mitchell, guaranteed by Messrs. Philp and Forsyth [of the well-known and long established firm of Messrs. Burns, Philp and Co] to take all of the output of the colliery for five years at six shillings and sixpence per ton, delivered aboard the steamer at the jetty.

The Vendor has agreed to dispose of all his interest in the lease, plant, railway, jetty and freehold land for the sum of forty thousand pounds and thirty five thousand fully paid up shares in the company.

Mr. Wilson, the colliery manager in his report hereto appended, undertakes to put the large or round coal free on board the steamer at the jetty at four shillings and sixpence per ton and the nuts or smalls at one shilling per ton. Taking the output for five years – the term of the contract – the result of profit will be £76,375. [a table of output/profit over the five years followed].

The quality of the coal is considered equal to any in the southern district, which is so well appreciated that the large ocean going steamship companies gives it preference to Newcastle coal.

The Vendor, Mr. Thomas Saywell, [who is well known as the original proprietor and guarantor of the dividend of Saywell’s Tobacco Company, which has proved such a success], agrees to guarantee a dividend of 10 percent per annum for three years and will deposit with the directors 15,000 fully paid up shares as a ???? that the same will be earned and paid. He also stipulates that during the term of this guarantee he shall be one of the directors of the company.

It is almost superfluous to point out any further advantages this property possesses considering that a contract is made for five years which shows a profit of £76,375 and that the vendor guarantees a dividend of 10 per cent for three years.

If in its infancy (which everyone conversant with coal-mining knows is the trying time) it shows such results and they are guaranteed, what a prosperous after-life is in store for this company.

This property possesses the following advantages:-

- Facilities for getting rid of the coal, having a private jetty; also being connected by rail with Wollongong and Sydney when the Illawarra line is opened.

- A guaranteed contract for five years.

- Possessing all the seams of coal in the Southern District, the one now opened containing 4,209,000 tons of large coal, which alone will last for 30 years with an output of 150,000 tons per annum.

The contracts and reports herein-mentioned can be inspected at the office of Mr. John J. Weston, O’Connell St.

As 23,000 of the subscribing shares are already agreed to be applied for by the provisional directors and their friends, the Share List will close upon the 31st instant and the shares then be allotted rateably.

In any case where the application is too small that no allotment can be made, the deposit will be returned to the applicant in full, and when the number of shares allotted is less than the number applied for the surplus will be credited in reduction of the amount payable on the shares allotted.

Norwich Chambers, Hunter Street, Sydney

October 6, 1887.

- C. Cowlishaw, Esq.

Dear Sir, - Having, in your company, visited and examined the workings and plant of the South Bulli Colliery, we forward herewith our report thereon.

SITUATION

The property consists of 700 acs of land in the Illawarra district, leased from the Osborne family for a period of fifty (50) years, at a royalty of 1d. ? per ton of all round coal. Besides this, 640 acs have been taken up as a timber lease from the Crown, which could be secured under mineral lease should it be found desirable to do so. The 700 acre block adjoins the Bulli Colliery on the south and the seam of coal is cropping on the eastern side of the property, and dips westward at an angle of 1 in 20 so that the workings are all in the dip from the outcrop. The seam has been proved, both in Bulli, to the north and in Brooker’s Nose to the south and although no outcrops are known to the westward the ranges appear to have a settled character and there is no reason to suppose that the seam will be lost or seriously broken to the dip of the present workings which, in themselves, prove a considerable area of coal.

At the point where the mine railway crosses the government line, a block of land 20 acs in extent, has been purchased as a freehold and surveyed into allotments for miners residences and bricks are also being made at one end of it, a contract for 300,000 bricks having been let for 22s per thousand.

A strip of land, three miles long and half a chain wide, has also been purchased, extending from the mine to the jetty and on this the railway has been constructed.

THE WORKINGS

The old Bellambi Company, who held this property several years ago, commenced a dip drive, as well as a diagonal one, from which bords were opened very close to the outcrop and a small quantity of coal was extracted. They were, however, limited in their operations by a dyke, which was met with in the diagonal drive and never driven through and presumably by water in the dip, so that very little work was done by them; and the present proprietors has, since the property came into his hands, devoted his entire attention to opening up the mine for a large output.

As the mine stands at the present time, the dip drive has been continued for 300 yds. from the mouth, the diagonal drive for about 330 yards, and a crosscut, 240 yards long, has been put in. Joining these two, while below the junction an air course is also being driven, parallel to the main dip drive.

The dyke has been intersected, both in the diagonal drive and the crosscut, and, although the coal is inferior close to it, the bedding has been in no way disturbed, the seam being met with at the same level and of the same thickness on either side of the dyke.

At the present time work is being continued in the dip drive, with the view of further developing the mine and as soon as the shipping arrangements are completed the crosscut will afford room for 40 bords, employing 59 men and will be equal to an output of fully 320 tons per day.

An air shaft, 12 feet in diameter, has been sunk and lined with brick and a large ventilating furnace built with suitable doors, stoppings etc, where required and the present ventilation is all that can be desired.

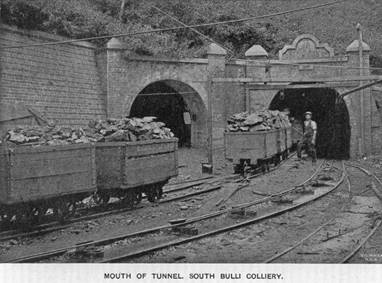

The workings are all very substantially timbered and rails are laid for a permanent tail rope system of haulage, although with the present dip the tail rope is unnecessary, the skips themselves drawing out the main rope. The mouth of the mine is arched and protected by brickwork.

The accompanying plan of the workings is from the survey of the manager, Mr Wilson, who furnished us with a tracing.

NATURE AND QUALITY OF THE COAL

The seam of coal which is being worked is fully 9 feet thick in places and certainly not less than 7 feet thick in any part of the mine but as some coal has been left underfoot in many places its true height is not always apparent. We may safely estimate the seam, however, at 8 feet thick on an average and is quite free from bands throughout the mine. There is a good solid roof, from which the coal parts readily and the seam can be worked at a minimum cost as regards hewing.

An average sample of the coal, taken from roof to floor at the working face, gives the following analysis, that from the Bulli Mine being given for purposes of comparison.

|

South Bulli |

Bulli |

Coal Cliff |

|

|

Water |

0.82 |

0.65 |

0.38 |

|

Volatile hydrocarbons |

20.93 |

21.65 |

18.22 |

|

Fixed carbon |

65.04 |

65.53 |

69.24 |

|

Ash |

12.50 |

11.23 |

10.30 |

|

Sulphur |

0.71 |

0.74 |

0.28 |

QUANTITY OF COAL

From the foregoing data it would appear that the 700 acs contain a total quantity of 5,600,000 tons of available coal; and allowing one fourth of this as slack and nuts, we should have 4,200,000 tons of round coal to be exploited exclusive of any ground that may be subsequently secured to the dip as the workings are carried farther away.

PLANT

A thoroughly efficient plant has been provided for working the mine, transporting the coal to seaboard and shipping it from a jetty, which has been erected with good shelter (from the south-east) with 22ft 6in water at low tide. This plant is as follows:-

- Jetty 2065 ft. long from first timbers and 365 ft. from high water mark to the end of the pier. It was constructed of round timber (turpentine) securely braced, the piers being dowelled with iron rods into the rocks upon which they rest, the end ones being bedded into the solid rock. This jetty is built with two ways, each graded so that the trucks can run down on the brakes from high water mark to the shipping place and back by the lower road whence they will be drawn by the engine. Tumblers are provided for tipping the coal.

- Line of railway about 4 miles long including sidings, laid with 40 lb steel rails for most of the distance, 70 lb rails being used at the jetty and again at the crossing of the main line. Points and sidings are provided where required.

- Brick kiln and drying shed suitable for 30,000 bricks in a set.

- Engine-house, manager’s house, office, store, blacksmith’s shop with tools, stores etc.

- Self-acting incline, laid with three rails at top and two rails below loop crossing with gauge 4 ft. 8 1/2 ins. for railway trucks.

- Drum-house, engine-house, sheds for sawmill, screens and sidings at head of incline including a considerable amount of excavation in their preparation.

- About 870 yards of driving with substantial timbering; 30 lb rails through dip drive and lighter rails in other parts of the mine. Air shaft, 12 ft. in diameter, lined with brick, and furnace 12 ft. x 12 ft.

- Fowler’s locomotive tank engine.

- Robey’s mining engine, 60 hp. and boiler, 3 ft. drums with clutch gearing and ropes, for tail rope systems of haulage.

- Small Tangye pumping engine in mine.

- Drum, 8 ft. diameter with band brake and ropes for self-acting tram line.

- Two, self-feeding circular saw benches and vertical saw frame, all in working order.

- 100 railway wagons, to carry 5 ton each: - [20 wagons completed, 30 wagons in course of construction, 50 wagons to be made].

- 200 skips of 12 cwt capacity:- [100 completed, 100 to be made].

- A considerable quantity of stores and material on the ground, including winches, steel rope, brats etc. etc. The manger, Mr. Wm. Wilson has submitted to us the following estimate and comparative cost of these items-

Cost to form and make railway £10,000

Locomotive 1,100

Robey’s engine 1,500

Tangye’s engine and pump 150

Screens and pit top 3,000

100 wagons 4,000

Cost of jetty 15,000

Air shaft and opening mine 4,000

20 acs freehold at £100 2,000

Sawmill and reservoir 2,000

Blacksmiths tools, houses, dwelling-

house, engine and sheds 2,000

Incline and drum house 1,200

Pit rails and skips 1,800

Total £47,750

Most of which appears to be very reasonable, premising that only 20 out of 100 wagons are as yet complete and only 100 skips, while work yet remains to be finished on the jetty and at the pit top where sidings and screens still require some little work to complete them.

The sum mentioned for screens and pit top seems somewhat high, but as no allowance is made for setting the engines, drums etc., this must be taken to include that amount and is thus reasonable.

In this estimate the cost of the land along the line of the railway which is half a chain wide and three miles long, has been omitted, which being 12 acres at £100 per acre, would represent £1,200.and the cost of the incline which we may estimate at £1,100 would bring the total expenditure to £50,000 when the work is complete.

It is, however, impossible to estimate the expenditure without going minutely into the details of the work, with all the specifications etc., before us; but we do not think the work seen could be completed under the sum mentioned and may state that everything has been done in a most workmanlike manner and all care has been exercised to save labour in working and handling the coal.

SYSTEM OF HAULAGE

In drawing from the mine the skips alluded to will be used and are drawn in trains to the surface whence they run on the brakes to the top of the screens; here they are tipped with a tumbler and the coal, nuts and slack delivered into separate wagons or bunkers below. The wagons run on the brakes from the top of the incline to the screens and the roads are so graded that they can be returned to the top of the incline in the same manner. The brake on the self-act is sufficiently powerful to lower two wagons at a time and from the foot of the incline the locomotive takes them to the pier, where the two lines are graded again to allow the trucks to run by themselves to the end of the jetty and back to the siding.

COST OF MINING THE COAL

In view of the very cheap and efficient system of haulage which has been adopted, the size and even quality of the seam and the convenience of shipping, we consider that the coal should be delivered, free on board, at 4s 6d per ton, when the output reaches 300 tons per day, which quantity could be delivered when very little more of the mine has been opened out.

TIMBER

An unlimited supply of timber, suitable for all mining purposes, is found on the ground and, as before stated, 640 acres have also been secured as a timber lease.

GENERAL CONCLUSIONS

We consider that the property, as it stands, when all the works are completed, is fully worth the money which you informed us had been asked for it, and worked in an efficient manner, will pay very handsome dividends. The facilities for shipping are very great as the depth of the water at the end of the jetty is sufficient for vessels of very large tonnage and the protection the jetty receives from the Bellambi Reef is of the greatest importance. It is only with heavy north-east winds that shipping would have to be suspended so that vessels could load there nearly all the year round and the plant will be able easily to deliver five hundred tons of coal per day when it is completed.

We had no opportunity of seeing outcrops of other seams of coal on the property, but have no doubt that the others which belong to the Illawarra section will be found in South Bulli.

Yours faithfully

COX and SEAVER

Mining and Civil Engineers.

South Bulli Colliery 27th September, 1887.

Sir, - As colliery manager, I have to report, for your information and guidance, respecting the above property.

The headings and drives are all open, and the roads made, to enable me, within twenty-one days, to put out 300 tons of coal per day, which will be increased by the 31st December, 1887, to 500 tons per day.

The railway jetty and other plant and material are in first class order, and I see nothing to prevent my shipping 500 tons per day by the time stated.

I am convinced I can get and ship the South Bulli coal, at the jetty at or under 4s 6d per ton, free on board steamer at jetty, basing my calculations as follows:-

Miners (for hewing) 2s 4d per ton

Wheeling and screening 0s 5d

Haulage and shipping 0s 6d

Props and timber 0s 3d

Incidentals 0s 2d

Royalty 0s 9d

Total 4s 6d per ton

And should you desire, I am prepared to contract to put the coal, free on board steam at jetty at this price, small coal or nuts, I can put free on board steamers, at the jetty, at one shilling (1s) per ton made up as follows:-

Wheeling 0s 3d per ton

Haulage and shipping 0s 6d

Props and incidentals 0s 3d

Total 1s 0d per ton

The jetty is the best constructed and most suitable for shipping coal in the district, having 25 to 27 ft. of water at the shipping portion, being well sheltered by the Bulambi (sic) Reef. Coal can be shipped at our jetty when it is impossible to load at any the (sic) other jetties in the district.

I am, Sir, yours faithfully

- WILSON,

Colliery Manager, South Bulli Colliery

Applications for Shares to be sent in on the annexed form to Messrs. J. B. NORTH and SON, Brokers; or to Mr. JOHN J. WESTON, O’Connell Street, Sydney.

End

[Extract from the Sydney Morning Herald, Saturday 15 October 1887, pp 6. Ex trove.nla.gov.au]